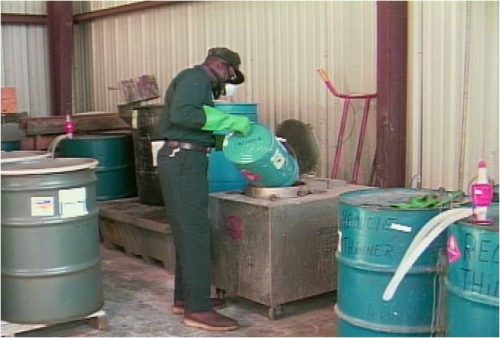

In the manufacturing of plastics, workers often transfer potentially hazardous liquid additives such as plasticizers, colorants, dyes, lubricants, antimicrobials and flame retardants into smaller containers or directly into tanks or machinery. At times, liquid solvents and cleaners used for maintenance may be transferred as well.

Chemicals such as acetone also are used in plastics machining and for 3D printed parts for vapor polishing, which – when applied to the surface of plastic – alters the finish to a high gloss.

These chemicals are toxic, corrosive, reactive, and flammable, emit volatile organic compounds (VOCs), or are even potentially explosive and the danger of accidental contact, even for short periods, can pose a severe hazard to workers. The transfer of chemicals at the point of use, whether it’s done in plastics manufacturing, fabricating or machining, can have serious consequences when manual “tip-and-pour” techniques or poorly designed pumps are used.

In addition to the potential for injury, there also can be serious financial ramifications for the facility involved. The risks include the cost to treat injuries or perform cleanup, as well as workers’ compensation claims, potential liability, OSHA fines, loss of expensive chemicals and even facility/production shutdown.

“It can be catastrophic to a company if toxic or highly flammable material is accidentally released at the point of use,” says Deborah Grubbe, PE, CEng, and founder of Operations and Safety Solutions, a consulting firm specializing in industrial safety. “Companies have to assume that if something can go wrong during chemical transfer, it will, and take appropriate precautions to prevent what could be significant consequences.”

Spiraling Costs of Loss of Containment

Grubbe, who has 40 years of experience working in the chemical, oil and gas industries, including at DuPont, NASA and for the U.S. military, says, “Any time you lose containment; you have an issue that can spiral out of control.”

Corrosive chemicals, for example, can burn skin or flesh. Some chemicals are toxic when touched or inhaled. Cyanotic agents can be particularly dangerous or even fatal, since they rob the body of oxygen. Many chemicals are flammable, and can be ignited by even the smallest spark from nearby motors or other mechanical equipment.

“There is no such thing as a small fire in my business,” says Grubbe.

In addition to cost of cleanup or treating injuries, there also are indirect costs that can be incurred. These include supervisors’ time to document the incident and respond to any added government inspection or scrutiny, as well as the potential for temporary shutdown of the facility.

Read more at EHSToday.com